Design to manufacturing concepts

Designing and manufacturing a product requires collaboration and information sharing between suppliers, partners, manufacturers and internally across different departments and disciplines. In order to reduce lead times this information sharing must be as efficient as possible. At the same time a companies intellectual property and commercial advantages must be protected and data breaches must be avoided. The sharing of information must be controlled and traceable.

ShareAspace D2M product is designed to address these challenges by enabling the controlled sharing of information between an organization manufacturing and assembling a product, referred to as the "Prime" and its suppliers, partners, manufacturers.

The information shared is typically product data, such as specifications, part information, CAD models, associated documentation.

The sharing is controlled by supporting a number of high level collaboration processes. Namely:

- Request for information

- Request for manufacture

In both high level processes the Prime can engage a number of suppliers simultaneously.

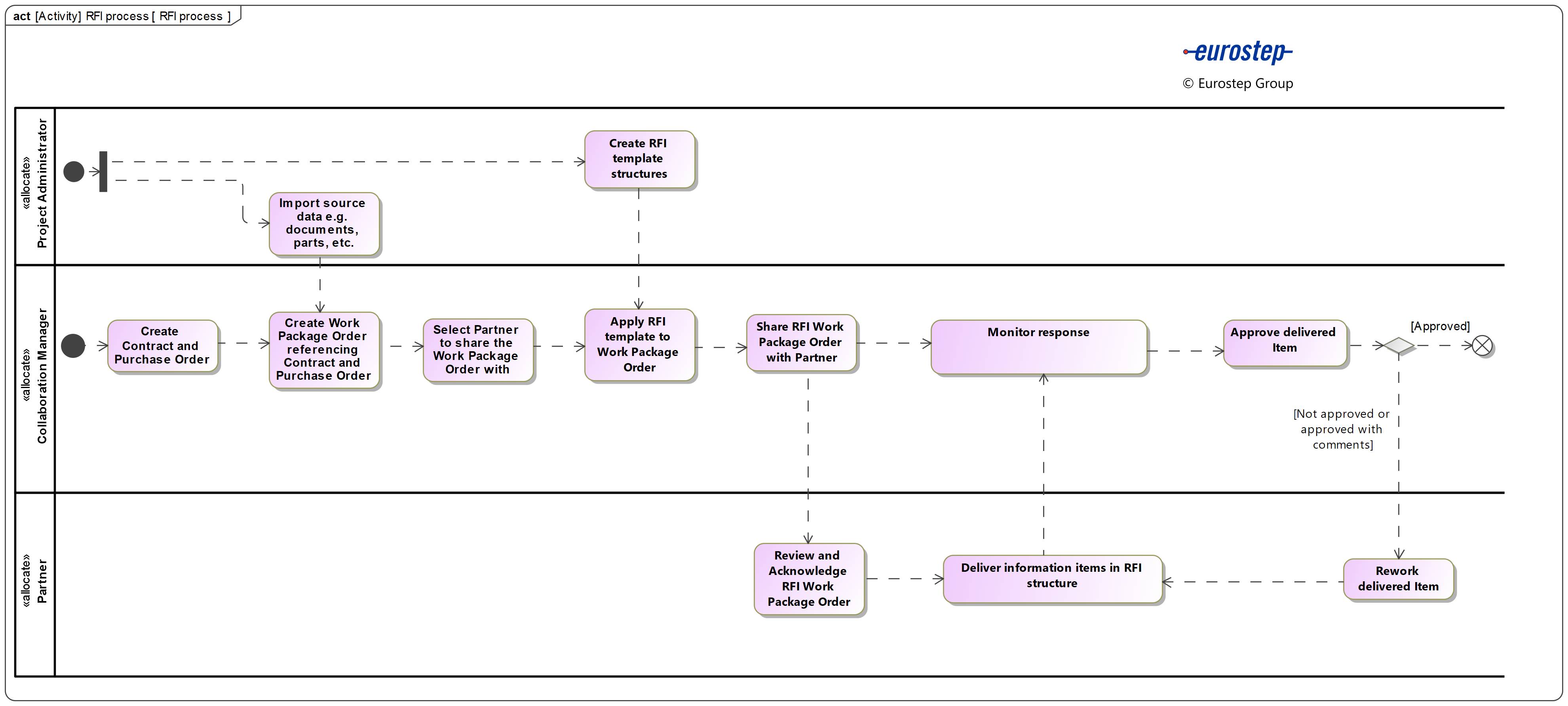

Request for information

The Request for information is a high level process that enables a Prime to request information from a supplier in a controlled, structured way. A typical usage is where a Prime is incorporating a number of parts from a supplier into an assembly and requires that the supplier provides, an installation drawing and maintenance manual. The Prime can formally request these two sets of documentation from the supplier. The supplier can then upload and share the relevant documents for review, approval and use by the Prime.

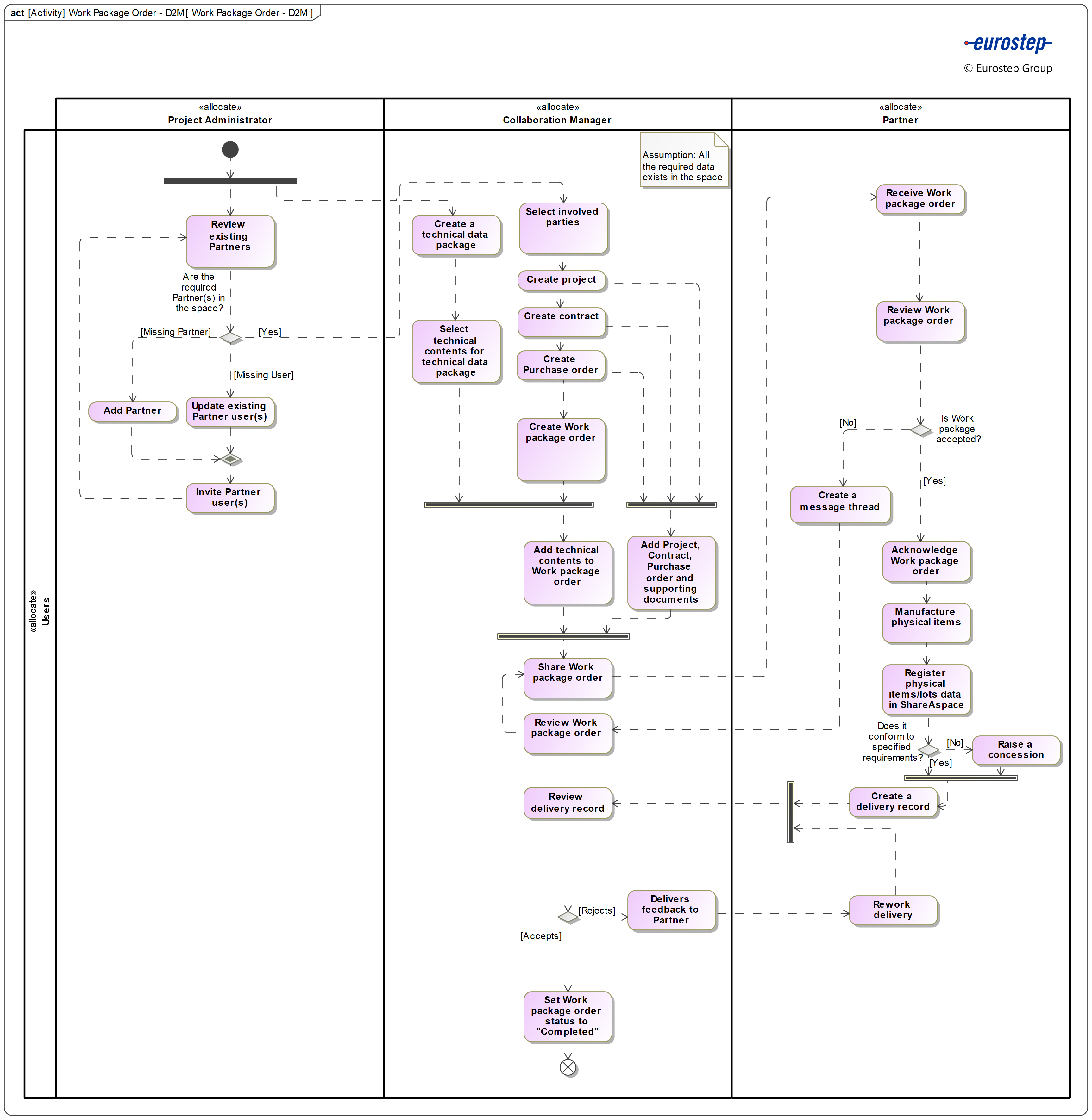

Request for manufacture

The Request for manufacture is a high level process that enables a Prime to request that a supplier manufactures and delivers a set of physical parts for integration into an assembly. The Prime may provide the designs of the parts to be manufactured, or may be requesting manufacturer from a pre-existing design. The process supports the Prime placing a purchase order on the supplier who then manufacturers and delivers the items. During the process the Prime may propose a design change that can be accepted and incorporated by the supplier. The supplier may request concessions on the manufactured items.

The high level process managed by ShareAspace D2M is shown in the diagram below.

ShareAspace introduction

The ShareAspace D2M product is built on the ShareAspace server, a platform for the controlled sharing of information.

Spaces

ShareAspace is organized into a set of spaces. A space is like a database setup for storing and sharing all the information and communications related to achieving a goal, initiative, or objective.

Users can be part of multiple spaces, and might have distinct roles in each space that they belong to. A user will only know of and be able to access a space if they have an explicit role in a space.

Participants

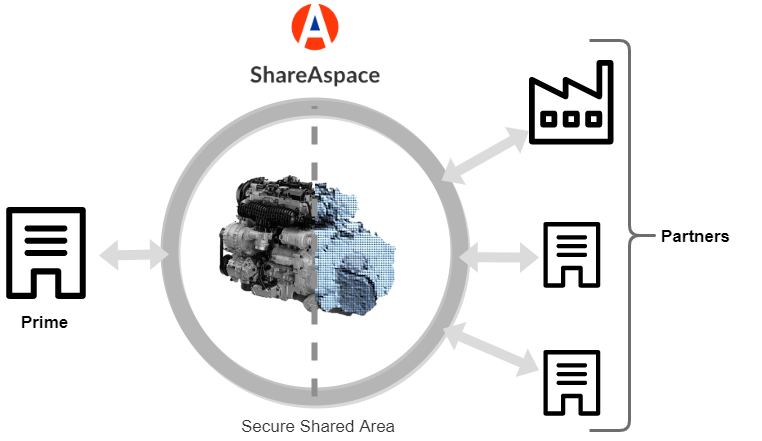

ShareAspace is designed for collaboration and data sharing between different organizations. Each organization that is a member of a space is referred to as a participant. Each participant manages their own information within the space and then controls who that information is shared with. In other words the intellectual property of each participant is protected.

In ShareAspace D2M the sharing pattern is between a Prime and their partners.

This is shown in the diagram below. The prime manages the space, invites partners into the space and controls what information is shared with them.

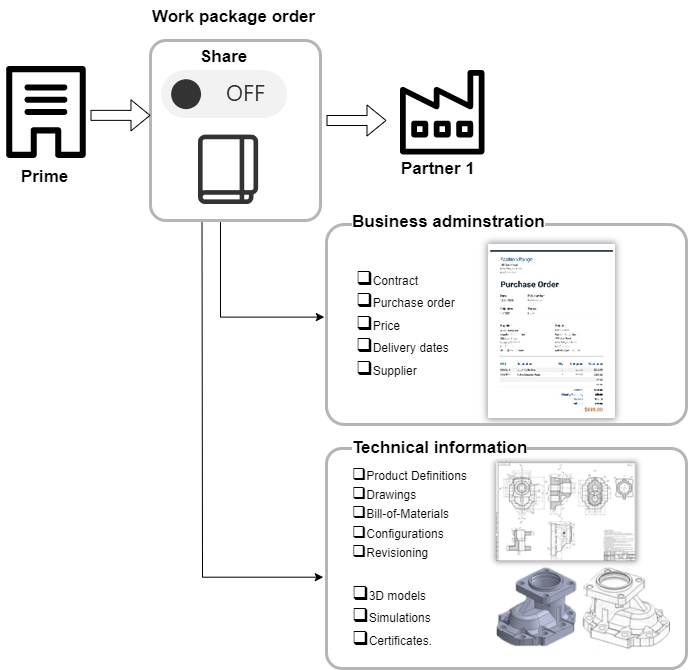

Controlled data sharing

A core capability of ShareAspace Design to Manufacture is the ability to share information between organizations. This sharing is controlled by a work package order. A work package order is setup by the prime and identifies a set of information to be shared with one supplier in order that the supplier can undertake some work, such as manufacture a part or assembly. The work package order is governed by business information such as a purchase order, a contract and a project and explicitly references the information to be shared. This is shown in the diagram below.

Once the work package order is shared, the supplier has access to the information referenced by the work package order and only that information.

The prime can unshare the work package order at any time at which point the supplier will no longer have access to the work package order and any information referenced by it.